What Is NozzlePRO?

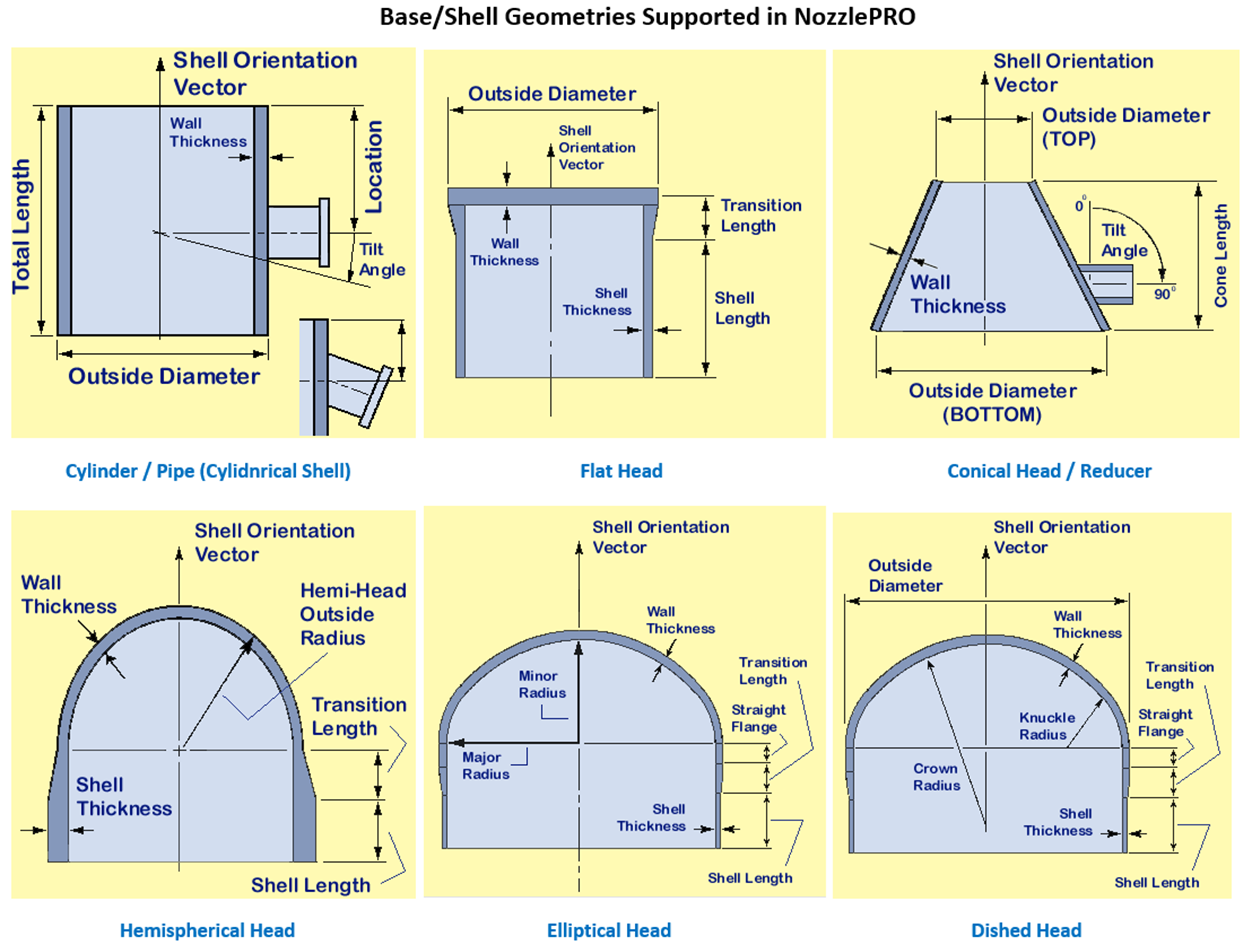

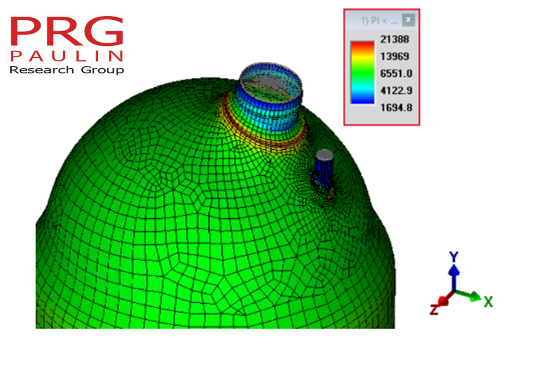

NozzlePRO is a standalone solution that enables users to quickly and easily perform finite element analysis (FEA) of individual pressure vessel and piping components without extensive knowledge of FEA modeling, analysis techniques or theory.

With capabilities designed to automate FEA validation and ASME code compliance reporting on pressure vessel and nozzle models, NozzlePRO is an efficient and accurate Design By Analysis (DBA) solution for pressure equipment designs.

What does NozzlePRO include?

NozzlePRO Software Capabilities

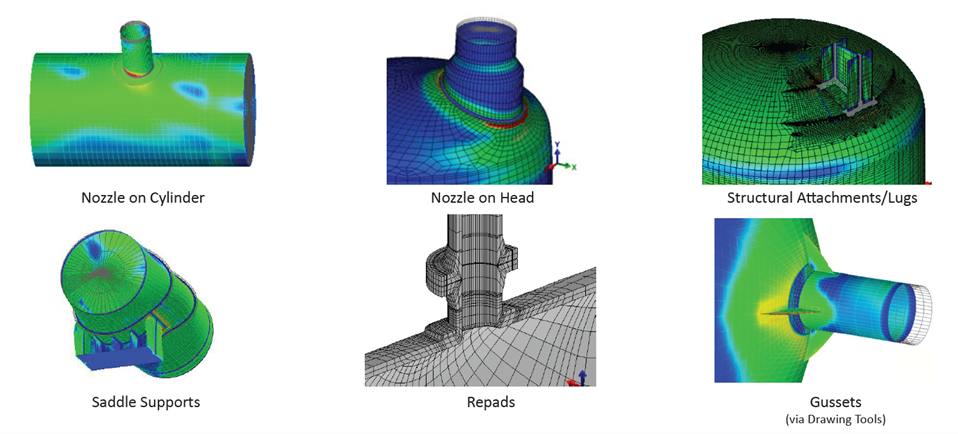

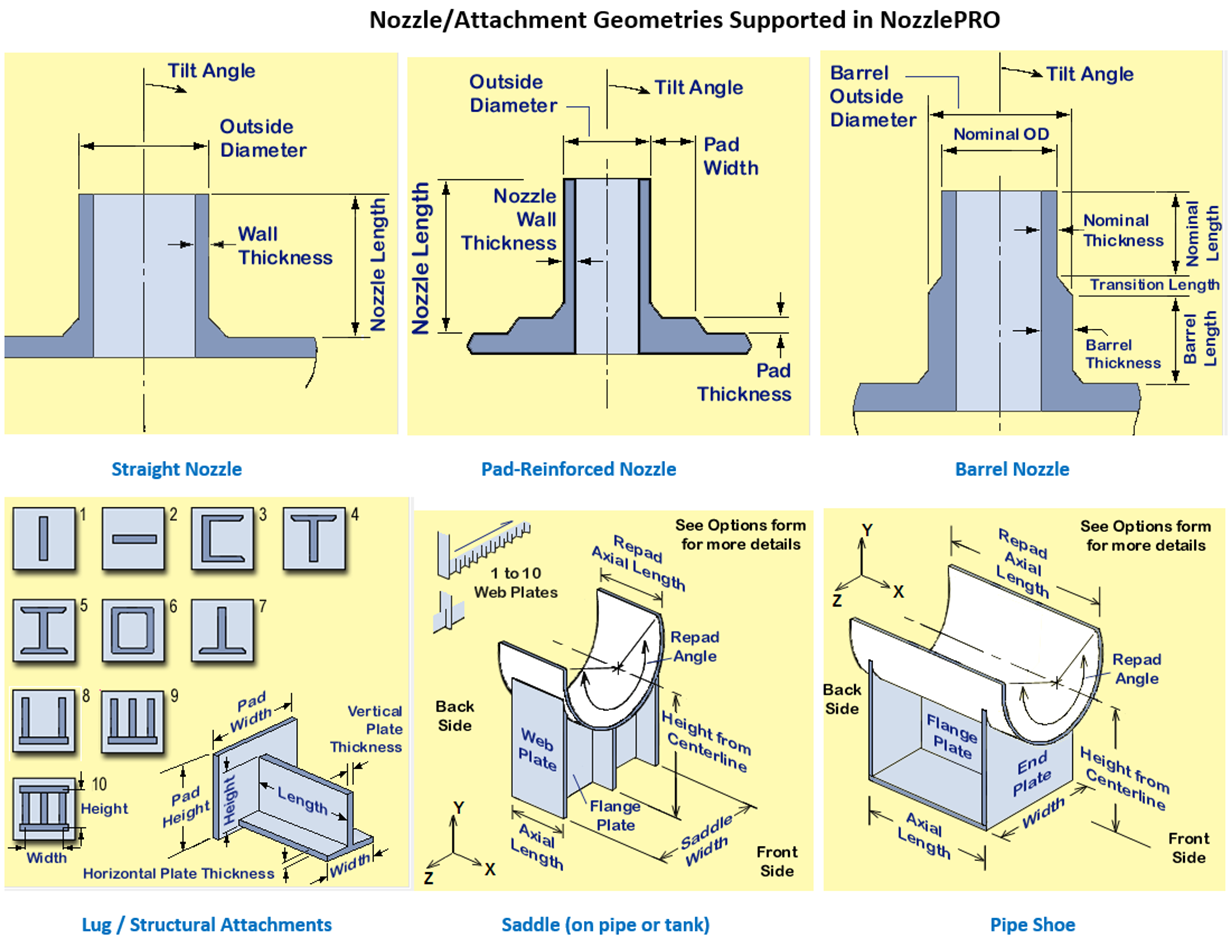

NozzlePRO is designed to quickly and easily evaluate nozzles, saddles, pipe shoes and clips on a variety of head types, including spherical, elliptical, ASME, dished, cylindrical and conical. Within minutes you’ll be able to generate the following:

- Nozzles through Blind Flanges in Axisymmetric and Brick Models

- Double Bed Supports

- An Axisymmetric Horizontal Vessel with Saddles

- Steady State and Transient Heat Transfer for Axisymmetric 2D Elements

- Head Thickness Contours

- Blind or Matching Flange End Conditions for Axisymmetric or Brick Models

- Radiused Welds

- Overturning Moments on Skirts (Brick Models)

- Internal Ring Loads

- Integral and Non-Integral Repads

Features in NozzlePRO

PRG’s standalone FEA solution aims to support easy and accurate Design By Analysis functionalities, including:

-

Analysis

- Validates models against ASME Section VIII Div 1 and Div 2 codes and provides stress classification options to address different interpretations of the code

- Uses WRC 107/537 methods for spheres, elliptical and dished heads

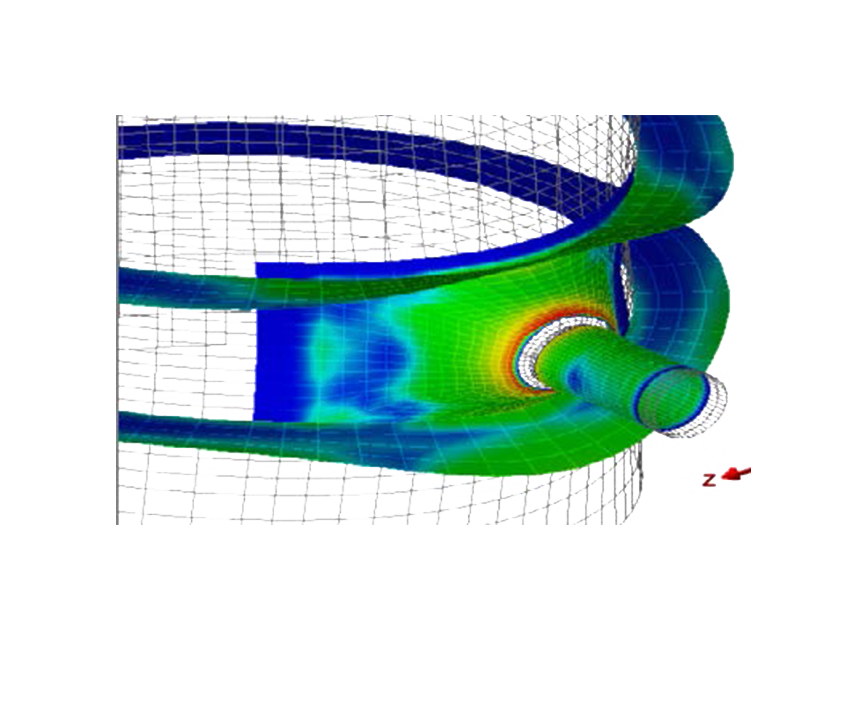

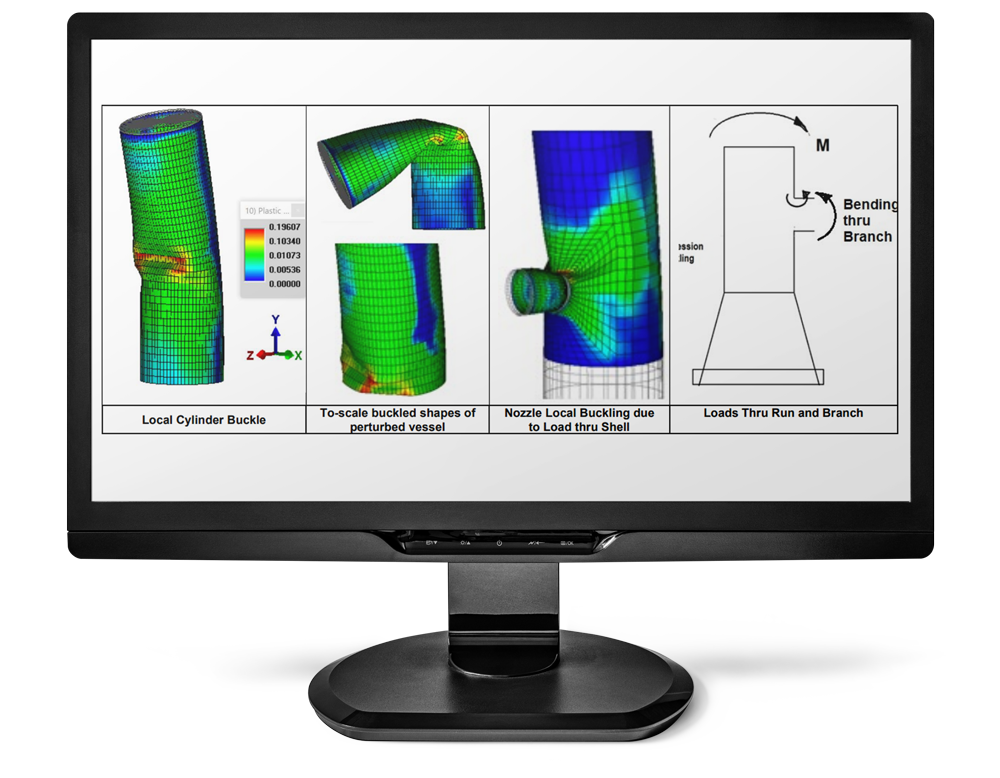

- Analyzes load model perturbation and buckling for heads, cylinders and branch connections

- Evaluates flaws or cracks in pressurized or loaded components using a Level 3 fitness-for-service analysis

- Validates models against ASME Section VIII Div 1 and Div 2 codes and provides stress classification options to address different interpretations of the code

-

Design

- Provides automatic Stress Intensity Factors (SIF), nonlinear Sustained Stress Indexes (SSI) and flexibility factors for nozzles and branch connections

- Uses elastic-plastic and non-linear FEA solvers to determine the most accurate collapse loads and stresses

- Uses the Drawing Tools feature to provide an interactive CAD feature to edit the model or apply local thinning and cracks.

- Handles multiple load cases at a time and loads on the nozzle and header can be performed simultaneously.

- Provides guidance on the Acoustic Induced Vibration (AIV) Update for determining frequency ranges and stress results for high frequencies

- Provides automatic Stress Intensity Factors (SIF), nonlinear Sustained Stress Indexes (SSI) and flexibility factors for nozzles and branch connections

-

Integration

- Includes a native integration with CEI’s DesignCalcs and Finglow so that models can be imported and FEA can be performed along with PD5500, EN13445 and ASME Section VIII Div 1 and 2 codes

- Supports XML and JSON files so that models can be imported from Codeware Compress and Hexagon programs

- Includes a native integration with CEI’s DesignCalcs and Finglow so that models can be imported and FEA can be performed along with PD5500, EN13445 and ASME Section VIII Div 1 and 2 codes

Programs in NozzlePRO

Along with a variety of features, NozzlePRO utilizes several programs to provide the ultimate FEA solution for pressure equipment designs. A few include:

- The Saddle Wizard is a step-by-step interactive modeler that allows the user to design their horizontal vessel and saddle for any loading conditions.

- The Pipe Shoe Wizard creates an FEA model of a pipe shoe on a cylinder to calculate local stress.

- The Drawing Tools allow the user to add gussets, rings, clips and other attachments to an existing model.

- Vessel Link allows the user to import models of any file type from DesignCalcs, Finglow, Codeware Compress and other Pressure Vessel design software to perform FEA.

- FE107 replaces WRC 107 as a calculation tool that can be applied when WRC 107 or WRC 297 calculations or assumptions are limited. ASME Section VIII Div 2 allowables are printed along with flexibilities and allowable loads for forces, moments, and pressure.

Additional Programs

Program |

Program Summary |

High Frequency |

Provides AIV calculation predictions of pressure levels from the surface of the vessel. This program is mainly used to:

|

Flaw Detection |

Predicts crack growth for given stress states in components to know when the crack will reach half wall and/or thru wall for leaks. This is a quick calculation based on observed crack growth in tested low carbon steel components. |

Nonlinear Analysis |

Computes burst pressures, sustained stress indices, twice elastic slope load levels b, and a variety of load and unload conditions. |

Degree of Conservatism |

This tool aids in determining the degree of conservatism on models. |

FESIF |

Calculates SIFs and k-factors for standard B31 branch connection geometries. |

FETee |

Along with performing FEA of contoured tees per user input, B16.9, or EN10253, this program mainly:

|

When to Use NozzlePRO

NozzlePRO accounts for thermal, weight, operating, occasional, pressure, wind and earthquake loads so that compliance requirement needs in the O&G, Chemical, Pharma, and many other industries can be easily determined and met.

With any DBA program, NozzlePRO is highly configurable and can be tailored to fit almost any need. Want to learn more? Schedule a discovery call with us today.

- When there are multiple thermal or operating loads acting on a nozzle.

- When WRC limits, proper boundary conditions and weld models should be accurately addressed.

- When the nozzle pad is reinforced and WRC 107 or 297 is considered for use.

- When there are loads acting on a nozzle and pipe simultaneously.

- When pad-reinforced lugs, clips, or other support are placed on the knuckle radius of a dished head and WRT 107 methods are fraught with potential errors.

- When seismic horizontal loads on vessel clips or box supports are to be evaluated.

- When the analyst needs to run various model types, comparing results to determine the stability and accuracy of the solution.

- When there are overturning moments on skirts.

- When there are different thermal expansion coefficients or temperatures between the header and branch.

- When horizontal vessels are saddle supported, with or without wear plates, as well as tapered saddles with many design options.

- When evaluating the effects of axial or transverse loads due to internal sloshing, wind loads, seismic loads, or general external loads and when the Zick method does not consider either axial or transverse loads.

- When designing pipe shoes for self-weight, liquid weight and axial loads

- & many more