2 min read

Welding Research Council (WRC) Bulletins and Pressure Vessel & Piping Designs

Paulin Research Group

Dec 15, 2022 7:57:33 AM

The Welding Research Council (WRC) regularly publishes bulletins to make welding compliance and pressure vessel design easy. These bulletins are incredibly helpful for simple calculations for a limited scope of scenarios. Even though performing a finite element analysis is a more robust way of ensuring safety in your designs, a WRC calculation can be quick for a compliant solution for your most simple designs.

How to Use WRC Calculations in your Pressure Equipment Designs

WRC bulletins help validate piping and pressure vessel stress to ensure safe designs. Using these straightforward formulas, fabricators can perform a geometry check to analyze stress capacity. The most popular bulletins used in nozzle head designs are WRC 107/537 and WRC 297.

To use a WRC calculation in your design, you must purchase the appropriate bulletin for your design and then step through the code equations provided to perform code compliance and validate the nozzle.

Alternatively, certain design software today includes built-in WRC calculators to expedite this process. For example, Paulin Research Group created FE107 for just this purpose. Simply input the variables and click.

Limitations to WRC Bulletins and Calculations

As mentioned above, each WRC bulletin is made with a single scenario in mind. This means you’ll likely have to use a variety of procedures to design your pressure vessel and piping correctly. If your pipes or nozzles have multiple bends, unfortunately, the bulletins alone won’t provide you with adequate data to ensure that your designs are safe.

And this isn’t the only limitation.

Relying on WRC calculations for your designs can get expensive, not only to purchase the individual bulletin but also for the material used. WRC calculations are simple but conservative. As such, they tend to prescribe more material than other methods of modeling that can tell you the exact material needed to withstand pressure and fatigue over time, like finite element analysis.

Additionally, WRC calculations like WRC 107/537 and WRC 297 don’t account for vessel stress. While on paper your designs may look safe, pressure issues can occur after fabrication that results in the warping of your nozzles and fittings. And using WRC calculations won't account for pressure vessels and nozzles that undergo change when pressure is applied.

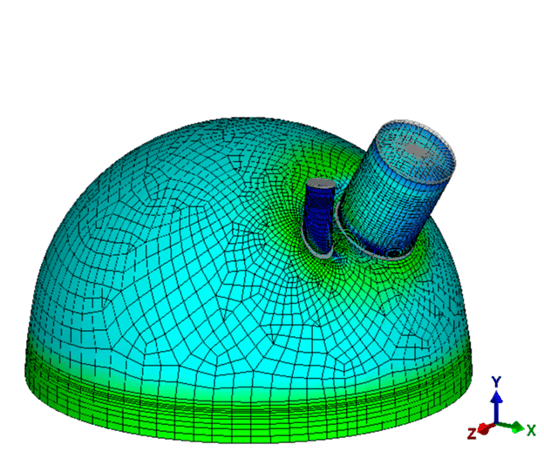

So, using WRC calculations won't work when you need to model multiple nozzles simultaneously, as they only account for one variable at a time. For more advanced pressure vessel head designs, you'll need a more in-depth solution for stress validation like PVPTPro.

When to Use Finite Element Analysis (FEA) Instead of WRC Calculations

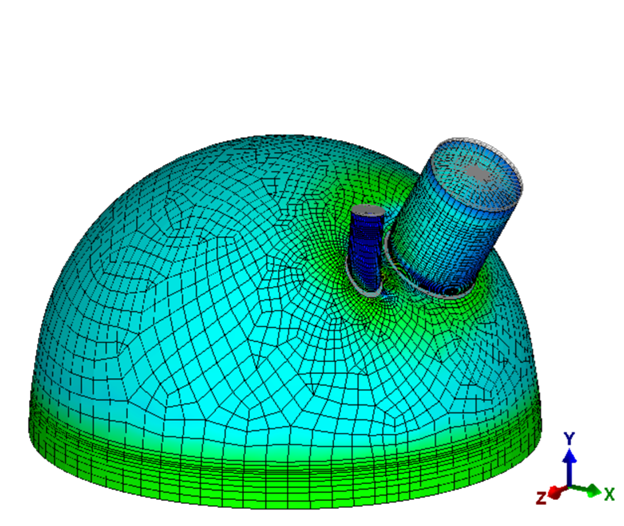

The obvious scenario that warrants the use of FEA is when the geometry being evaluated exceeds the scope of WRC. But, there is also an argument for using FEA instead of WRC to produce more accurate results, and this can potentially reduce the material costs of over-conservative code calculations. There is also the possibility of unidentified interactions for unique geometries that have not been validated in WRC but remain within the scope of the curve fit calculations.

FE107: A WRC 107/537 and 297 Calculator with FEA

Paulin Research Group created FE107 as a part of NozzlePRO to help you quickly and easily calculate values for WRC 107 and WRC 297 pressure vessel designs and validate them with finite element analysis. And the best part, FE107 runs the analysis for you in seconds.

If you need help determining if a finite element analysis is needed to validate your designs, or even if you just need a simple WRC calculator, feel free to reach out to us. Our pressure vessel and piping design experts are here to help.